Galvanic Isolators

DEI Marine produce industry-leading galvanic isolators for shore power connections from 16 to 200A. With DEI galvanic isolators you can prevent galvanic corrosion and maintain the safety of continuous grounding.

- Fail-safe design eliminates the need for a monitoring system

- High fault and lightning surge currents for improved safety

- Compact design with no heatsinks required

- Ignition protected improves installation flexibility

- Fail-Safe Plus Industry leading 7-year warranty

- Fail-Safe MAX for more demanding applications with 10-year warranty

See Galvanic Isolator Technical Literature and Galvanic Isolator Installation Instructions for more information.

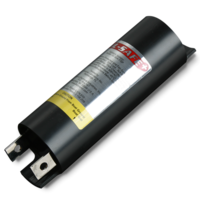

Dairyland (DEI) 100A Fail-Safe MAX Galvanic Isolator

SKU: DEI.GI-100A-FSM

RRP $4,045.00

$3,449.30

Dairyland (DEI) 30A Fail-Safe Plus Galvanic Isolator

SKU: DEI.GI-30A-FSP

RRP $1,370.00

$1,224.00

Dairyland (DEI) 50/60A Fail-Safe Plus Galvanic Isolator

SKU: DEI.GI-5060A-FSP

RRP $1,545.00

$1,495.00

Dairyland DEI 200A Fail-Safe MAX Galvanic Isolator

SKU: DEI.GI-200A-FSM

RRP $6,580.00

$6,399.00

Galvanic and shore power protection for boats and industrial applications.

A luxury yacht or commercial vessel is an important asset worthy of the best corrosion and safety grounding protection available. While protective coatings and anodes can help protect your boat, a sure method is required to deal with the galvanic corrosion circuit created by the shore power connection. The DEI Galvanic Isolator (or Electrolysis Blocker) provides the safest isolation of any technology on the market.

The Galvanic Corrosion Problem:

Whenever a boat is connected to shore power, the hull and drive system is connected to the shore grounding system and to other adjacent vessels (also connected to shore power) via the grounding conductor in the shore power cable. This connection, while required for safety, creates a galvanic corrosion cell involving the dissimilar metals between boats and between a boat and the shore grounding system.

- Anode – a metal surface which gives up metal ions (corrodes)

- Electrolyte – a medium which conducts ionic current between the anode and cathode

- Cathode – a metal surface that picks up metal ions

- Metallic Bond – a continuous metallic path that allows current to flow from cathode to anode

The Solution:

A simple method which virtually eliminates this galvanic corrosion problem is to insert an appropriately rated and certified Galvanic Isolator in series with the grounding conductor of the ship-to-shore power cable. The function of the Galvanic Isolator is to provide AC continuity of the grounding conductor (required for safety in the event of an AC fault) and to block the flow of corrosion-causing galvanic current.

Product Selection:

The DEI Galvanic Isolators are the most highly rated products available on the market. DEI Isolators are typically applied using an industry standard method of matching the device to the steady-state current rating of the shore power service. DEI Isolators are offered in 30A, 50/60A, and 100A ratings. For dual 15A services, one 35A DEI Galvanic Isolator can be used in place of two 35A units. For dual 30A services, one 50/60A DEI Galvanic Isolator can be used in place of two 30A units.

Review the DEI fault current rating for the selected model, to confirm that this value is adequate for the application. In the event that the anticipated fault current magnitude and duration in the shore power service is higher than that of the selected GI model, choose a higher rated model. Alternatively contact Outback Marine for expert help.

On a final note, check that the product has the appropriate Australian safety approval. All DEI products are certified to comply with ABYC A28; CE Marine ISO 8846; AS/NZS3004.2:2008

.jpg)