Marine Electrical System Design

Vessel electrical systems range in complexity from a simple single battery system as found on an outboard motor powered trailer boat to relatively complex systems using multiple battery banks with sophisticated AC and DC power distribution arrangements. The examples listed below showcase some vessel electrical system design and supply jobs that we have undertaken.

A marine electrical system design starts with a thorough understanding of the vessel and its intended use. This requires an analysis of the vessel plans or layout, documentation of the on board equipment and discussion with the owner/builder about vessel objectives and use case expectations.

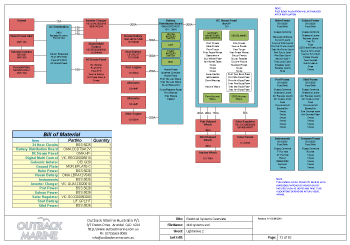

Outback Marine has implemented a design process that documents the overall electrical system requirements of the particular vessel or vehicle. For a nominal fee, Outback Marine provides a System Diagram of the electrical system that clearly identifies the electrical system architecture, electrical equipment items and circuits required.

Outback Marine has implemented a design process that documents the overall electrical system requirements of the particular vessel or vehicle. For a nominal fee, Outback Marine provides a System Diagram of the electrical system that clearly identifies the electrical system architecture, electrical equipment items and circuits required.

This document identifies all substantial elements of the system and lists them as a bill of materials. In addition to defining electrical loads, the device list forms the basis of specifying and costing the electrical panels. Once agreed at the system level, a detailed quotation for the equipment required to provision the project can be established.

All products supplied by Outback Marine are fully documented so that a qualified person is equipped with sufficient information to install the system. Outback Marine staff are available for advice and/or the provision of detailed schematics for an additional consulting fee if required. We can also introduce local electrical contractors to install the equipment if required.

Systems for commercial survey vessels require special attention over and above leisure vessels to ensure that survey compliance is met. Outback Marine is experienced in this area including the design and provisioning of compliant schematics. We choose to keep at arms length however when it comes to the actual electrical survey and accordingly recommend a third party qualified surveyor to approve the installed system.

Our clients get a system that works as intended and one that is documented so that any problems that might be encountered in the future can be readily diagnosed. We expect that our installed systems are very economical when total cost of ownership is considered.

Out Chasing Stars

For an in-depth customer review of the Outback Marine lithium battery energy system, take a look at the Replacing AGM Batteries with Lithium-Ion on a Boat blog post.

Recommended Reading

-

Electrical System Design explores methods of power generation, distribution and energy storage for liveaboard cruising boats. Discover a design approach that properly defines the required system.

- Lithium Battery Systems (including AGM batteries) highlights the need for a systems approach that includes power distribution, management and control as part of the battery installation.

If you would like to pursue a system design with Outback Marine, please make an enquiry on our Contact Us page and select System Design.

For individuals wanting to design and implement their own system, Outback Marine markets a broad range of specialised components required to build a total system from the simplest to the most complex.

The world class brands that we carry include:

The world class brands that we carry include:

- Outback Marine - Lithium Batteries, DC Distribution, Electrical Panels

- Lifeline - AGM Batteries

- Victron - Inverter Chargers - Solar Regulators - Lithium Batteries

- Blue Seas - Circuit Wiring and Protection

- Balmar - Alternators and Regulators

- Empirbus Digital Switching systems

- Caframo - DC Cabin Fans

- Maxwell - Anchor Winches and Deck Hatches

These products form the foundation of the systems that we design and supply which gives us the first hand experience necessary to properly advise the right product for client applications. It also happens that Outback Marine pricing is about the most competitive in the industry.

An alternative to a collection of individual components is to select one of Outback Marine's factory configured electrical systems. The majority of power distribution components that are typically installed and wired on location at the vessel have been transferred to factory built sub assemblies - AC and DC power distribution boards. Combined with Outback Marine electrical panels, the distribution board architecture simplifies the application to a set of functional blocks with straight forward interconnection wiring.

We expect this approach to be considerably less expensive then the component alternative when taking into account the total cost including labour and parts of a complete installation. Moreover, our planned system design of the overall job quickly identifies the client expectations and associated cost which means that our clients are not confronted with creeping costs. As the more sophisticated marine components are embedded onto our distribution boards and electrical panels, less specialised electrical trades people can effectively produce a professional result.

The block diagram above is indicative of a system that would be suitable for a live aboard vessel equipped with genset, house batteries, air conditioning, inverter charger, engine charging, solar panels and so on. Although tailored for a cruising catamaran, most system elements will transfer to other styles of vessel. Elements of the following description can be equally applied to other vessel configurations.

AC Power Sources

AC power can be sourced from the dock (shore power), an on board generator or an inverter (inverter-charger).

For AC power away from the dock, an inverter will transform DC battery power to 240 volt AC power suitable for many common appliances. For continuous loads of a relatively higher power rating (as in the case of air conditioning), a generator set will be required to meet the demand. None the less, an inverter is still common in generator set systems as it can provide short term power or low power needs without starting the genset. Examples might be for powering a television set or heating a cup of soup in a microwave oven.

AC Power Distribution

The AC distribution board handles the input switching of the appropriate AC power source and distribution of AC power to and from the AC House Panel. An important function of the AC board is to test the incoming polarity of the shore power connection and only make a connection if it is correct.

The AC House Panel has metering to monitor the characteristics of AC power, incorporates a source select switch to select the source of AC power and has a set of circuit breakers to control power for each of the AC power circuits. These switched circuits return to the AC distribution board for subsequent wiring of active, neutral and earth to the powered AC devices.

DC Power Sources

The main DC power source of a vessel is the battery bank. It has a very high current capacity to support engine starting and is capable of sustaining continuous loads without having to run an engine or a generator. But as a battery it also needs charging.

For inboard powered boats, the engine alternator is a powerful charging source. A specialised external alternator regulator maintains the correct alternator charging output by closely monitoring battery temperature and adjusting the charging voltage to obtain the fastest safe charging level.

An AC Genset provides AC power which in turn through a battery charger can be used for battery charging. It's important to match the battery charger to generator output power.

Solar panels can play a major role in battery charging provided that sufficient space is available to mount the required number of panels. As a minimum, a single panel is ideal to hold a maintenance charge while the vessel is left unattended.

Battery charging can be a simple process but also a dangerous one if the system is not correctly designed. In any case, a common objective is to minimise engine run time.

DC Power Distribution

The DC Power Distribution board is central to most DC components of the vessel. The first responsibility is to manage battery connection and isolation. The ability to completely isolate batteries in case of a fire or other emergency is a fundamental requirement of vessel safety. In the system shown, all power on the vessel is sourced from a House Battery. A Reserve Battery is available for essential services such as communications and engine starting if the need ever arises.

Power to engines, inverter charger and electrical panels is provided by bus bar mounted fuses that protect the heavy vessel cables from fire damage in the event of a short circuit. The electrical panels have circuit breakers that perform double duty. They provide circuit overload connection and act as a switch for controlling power to each device circuit.

The DCD also contains detail circuitry used in power monitoring and control. A battery monitor and optional remote battery switch control functions are included on one of the DC Electrical panels.

Circuit breaker panels complete the DC power distribution picture. While they enable individual load circuits to be turned on and off, their primary function is to protect the wire connecting to the load device by limiting current in case of an overload condition.

| Reference | Description |

| Electrical Systems | A sample specification of a typical vessel electrical system |

| Energy Guide for Cruising Vessels | A tutorial on developing a vessel power system |

Effectively power vessels under way and fully support living aboard at anchor.

- Power generation and distribution

- Energy storage with Lthium and AGM batteries

- Inverters and battery charging

- Working with solar energy

.jpg)